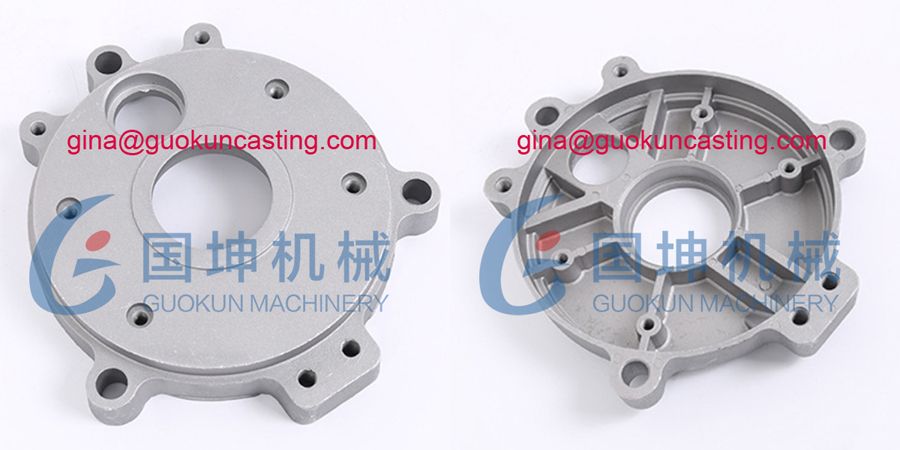

Aluminum Die Casting Parts

Die casting is a metal casting technique used to produce metal components by injecting molten metal (Aluminum alloy, Zinc alloy or Magnesium alloy) into a mould cavity. Baoding Guokun can use this cost-effective metal casting process to manufacture high-quality and complex metal castings with tight tolerances and excellent surface finishes, such as gears, engine blocks, furniture handles and electrical components. Please mail your inquiry to gina@guokuncasting.com to get the quotation.