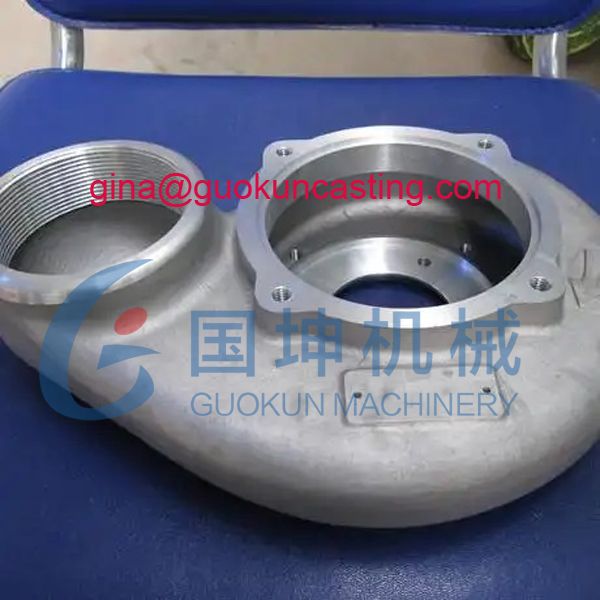

Aluminum pump body housing

China gravity die casting aluminum alloy pump body housing company

Application: centrifugal pumps, water pump casing, pool pump casing, oil pump, etc.

Aluminum alloy A356 pump housing is often produced by gravity casting process. The gravity die casting process is a metal casting technique that uses gravity to pour molten aluminum alloy into a mold to create the motor castings or engine castings. Baoding Guokun also can produce and export other metal pump casings as per customer's drawings or design, such as cast iron pump housing, cast steel pump casing, stainless steel pump volute, bronze pump body, aluminum alloy pump casing, etc. Please contact gina@guokuncasting.com to get more details.