Cast Iron Elevator Traction Sheave

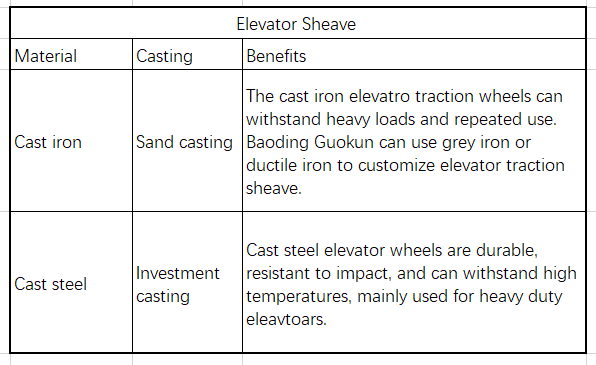

Elevator traction sheave is the rope sheave on the elevator traction machine, also known as traction rope sheave or drive rope sheave. It is a device for elevator to transfer traction power, which is transmitted by friction between traction wire rope and traction sheave groove. The shape of traction sheave groove is mostly semicircular groove, semicircular groove with cut, V-shaped groove. Baoding Guokun can produce and export various elevator casting replacement parts for various elevator systems, such as traction, guidance, car, door, weight balancing system and safety protection system. If you need elevator sheave from China sand casting factory, please contact gina@guokuncasting.com to get the quotation or call us 86-18132789710( WhatsApp & Wechat)