Description

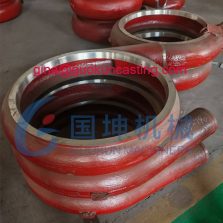

Baoding Guokun can offer you the most suitable material as per your pump’s requirements. And with 25 years casting experience, we can produce the custom pump impellers with the suitable cast metal and casting process. The most common material for industrial pump impeller is 300 series stainless steel, for example, SAE 304 stainless steel, SAE 316 stainless steel, ASTM A351 CF8, ASTM A351 CF8M, etc

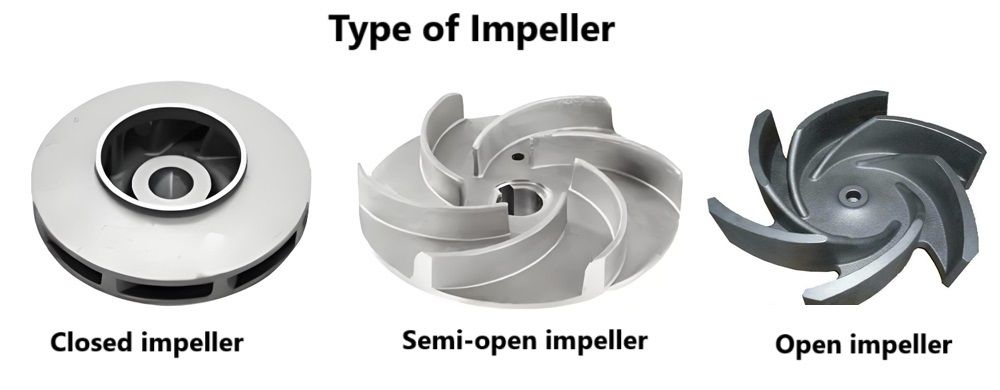

The pump impeller is the rotating component in the pump that directly transfers the energy from the motor into the fluid being pumped. Pump impellers are classified as one of three types: Open impeller, semi-open impeller, or closed impeller. Their classification is based on whether they have a protective shroud or not.

Impellers are casted in a variety of materials, including stainless steel, cast iron, bronze, aluminum, austenitic stainless steel, titanium, etc. When you choose the suitable material for pump impeller, you should think about the following several factors, strength, fluid compatibility, abrasion resistance, environmental conditions, type of liquid being pumped, casting and machining properties, etc.

| Product name | Material | Casting process |

| Pump impeller | 300 series Stainless steel, 400 series stainless steel, low-carbon steel, alloy steel, mild steel, cast steel | Investment casting ( lost wax casting) |

| Cast iron, ductile iron, grey iron | Sand casting, lost foam casting | |

| Bronze, Nickel-aluminum bronze, brass, aluminum, etc. | Sand casting or gravity casting for aluminum pump impeller |

Key Features of stainless steel pump impeller?

A stainless steel centrifugal pump impeller is a key component in centrifugal pumps, responsible for transferring energy from the motor to the fluid by rotating and creating centrifugal force. Stainless steel is a preferred material for impellers due to its corrosion resistance, strength, and durability, making it suitable for handling a wide range of fluids, including water, chemicals, and abrasive or corrosive media.

The stainless steel pump impeller Baoding Guokun produced is with the following material properties:

- Corrosion resistance: Ideal for handing corrosive fluids like seawater, acids, and chemicals.

- Strength: Withstands high rotational speeds and mechanical stress

- Wear resistance: Suitable for abrasive fluids or slurries.

- Hygienic: Smooth surface finish makes it ideal for food, beverage, and pharmaceutical applications.

- Temperature resistance: Can operate in high-temperature environments,

Baoding Guokun can produce vairous pump impeller, open impeller, close impeller and semi-open impeller or semi-close impeller in stainless steel 304 which is general-purpose grade for non-corrosive environmentrs, stainless steel 316 which is enhanced corrosion resistance due to molybdenum conent and suitable for harsh environments, duplex stainless steel (e.g., 2205) which is with higher strength and better resistance to stress corrosion cracking and Martensitic stainless steel (e.g. 410 or 420) which is hhigh strength but less corrosion-resistant used for specific applications.

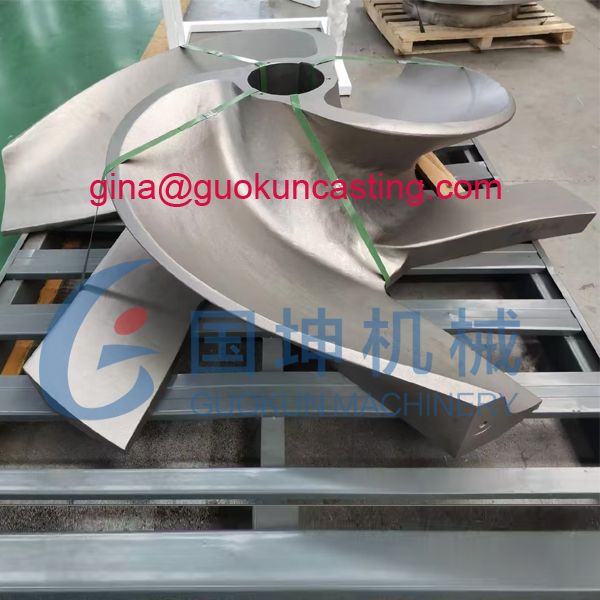

Baoding Guokun can offer you two different process for your customized pump impellers as per your drawings or designs.

Casting process: Investment casting or sand casting is suitable for your impeller with complex shapes.

Machining process: The impellers are CNC-machined from solid stainless steel billets for precision. This process is most suitable for small-quantity order.

Investment casting is an industrial metal casting process based on lost-wax precision casting, generally used for producing complex-shaped metal components that require tighter tolerances, thinner walls and better surface finish than other sand cast parts. Baoding Guokun can produce various investment casting parts in low-carbon steel, mild steel, alloy steel, stainless steel for pump, valve, agriculture, railway, road, forklift, tillage, mining, automotive, medical, food, and aircraft, etc.

Investment Casting Process Steps

The process of Baoding Guokun Investment casting involves several steps after producing a professional tool or mold in high-grade aluminum alloy, including:

| No. | Steps | Details |

| 1 | Patterns Makings | Hot wax is poured into the mold patten and allowed to harden, and then adding sprues to the wax model to create a tree-like structure. |

| 2 | Shell Building | Coating the wax pattern with a layer of fire-resistant paint, and then to be sprinkled with sand, so after a period of hardening, the surface will form a layer of fire-resistant thin shell. |

| 3 | Dewaxing | Removing the wax, the shell is placed into an oven, melting the wax so that it can run out of the shell. |

| 4 | Pouring | Pouring the molten stainless steel into the shell, and waiting for solidification under room temperature. |

| 5 | Post treatment | After cooling, knock the shell and cut the sprue gate by grinding machinery to achieve net shape impeller castings. Then shot blasting to move mill scales to assure the smooth casting surface. |

| 6 | Machining | CNC Machining |

Baoding Guokun, with 25 years casting experience, can produce various stainless steel investment casting for various industries. If you have similar need or OEM casting parts, cast steel impeller, cast iron impeller water pump, steel impeller, casting impeller, cast iron impeller, stainless steel impeller, cast impeller, impeller casting process, metal impeller, 4 blade impeller, please feel free to contact gina@guokuncasting.com to get a quotation.

Baoding Guokun Machinery Co., Ltd.

Office Add: 777# Chaoyang South Street, Baoding City, Hebei, 071000, China

Factory Address: Wangdu County, Baoding City, Hebei, 071000, China

Website: www.metalcastingfactory.com

Tel: 86-312-5951319 Fax: 86-312-5951296

Phone: 86-181 3278 9710 (WhatsApp & WeChat)

Email: gina@guokuncasting.com or gina.guokun@gmail.com