What is cast iron?

Cast Iron is an iron-carbon alloys with a carbon content 2-4% and silicon content around 1-3%. With its relatively low melting point, good fluidity, castability, excellent machinability, resistance to deformation and wear resistance, cast irons have become an engineering material with a wide range of applications and are used in construction, transportation, oil and gas, pump, valve, marine, power, gearbox, agriculture and railway. In general, cast iron is notoriously difficult to weld.

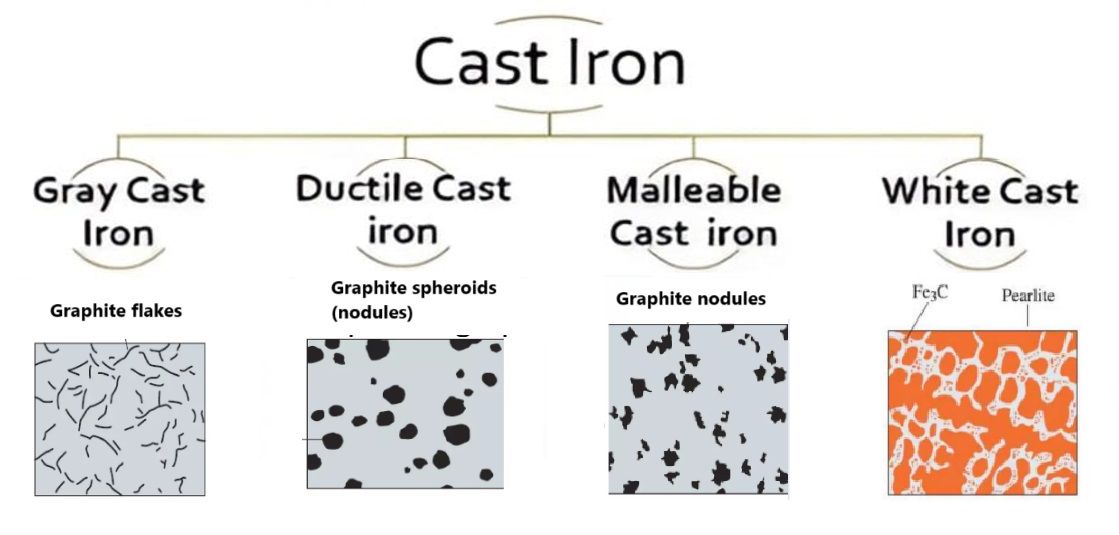

Types of cast iron

The main types of cast iron are: gray cast iron, white cast iron, ductile cast iron and malleable cast iron. Baoding Guokun can select the suitable cast iron as per customer’s requirements and specifications. And the chemical composition of cast iron will be carefully inspected by Baoding Guokun’s spectrometer.

| Gray cast iron | Gray cast iron is the most frequently type of cast iron. It is named for its gray fracture color due to graphite flakes in its composition. The grey cast iron has excellent compressive strength, and good machinability and limited brittleness. |

| Ductile cast iron | Ductile cast iron or nodular cast iron, is with graphite nodules that provide flexibility and toughness compared to gray cast iron, making the material less brittle overall. It has high tensile strength and impact resistance, making it a good choice for load-bearing components, such as automotive parts, gears, crankshafts, pump parts, gearbox, etc. |

| White cast iron | Named for its off-white color, which comes from iron compounds called cementite. White cast iron’s hard and wear-resistant surface makes it suitable for many wear-resistant applications, such as milling liners, motor frame, marine parts. |

| Malleable cast iron | Also known as malleable steel, it comes from annealed white cast iron. It’s resistant to wear and tear, has good plasticity and toughness, and is relatively easy to machine. |

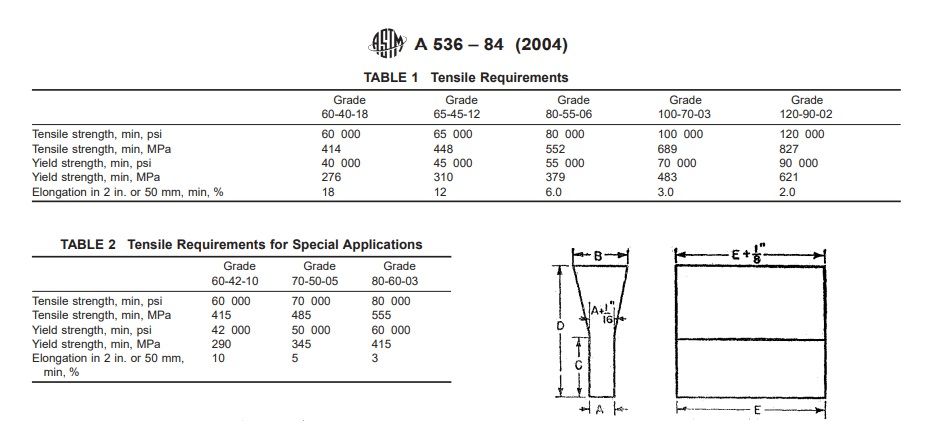

Ductile cast iron grades

Ductile cast iron: ASTM A536 refer to the standard specification for ductile iron castings. Baoding Guokun, a China sand casting factory, can manufacture various pumps, valves, agriculture parts, motor castings, railway castings, marine castings and other engineering casting components in several grades of ductile iron, including:

ASTM A536 Grade 60-40-18 is a nodular iron with a mostly ferritic microstructure and mechanical properties comparable to low alloy steels.

ASTM A536 Grade 65-45-12 is a nodular iron with a ferritic and pearlitic microstructure and mechanical properties comparable to low alloy steels.

ASTM A536 Grade 80-55-06, relating standards SAE J434C D5506 or ISO 1083 500-7, is a nodular iron with mostly pearlitic and smaller amount of ferrite microstructure.

ASTM A536 Grade 100-70-03, named pearlitic ductile iron, includes graphite spheroids in a matrix of pearlite. The pearlite matrix is comparatively hard and has high strength, combined with good wear resistance. This is combined with average ductility and impact resistance.

ASTM A536 Grade 120-90-02, named Martensitic ductile iron, has low to zero pearlite formation due to specific alloy additions, and can be quite hard and brittle in its untampered form.

If you need more information, please visit the ASTM A536 standard on our website https://www.metalcastingfactory.com/wp-content/uploads/ASTM-A536.pdf.

ASTM A536 ductile iron grades

Ductile iron is stronger and more ductile than gray iron, and it doesn’t fracture like gray cast iron. It is also a good choice because it dampens vibrations, dissipates heat well, and can be machined fairly easily. Ductile cast iron is a strong, malleable cast iron with many industrial applications:

Automotive: connecting rods, cylinders, crankshafts, disc brake, clamps, gears, gear boxes truck axles, and other pars.

Power: hubs, frames, pump housings, pump parts, machine frames for the wind-power industry and hydraulic parts

Wastewater system: pipe and fittings, manholes and combined sewer systems

Ductile iron casting parts produced by Baoding Guokun

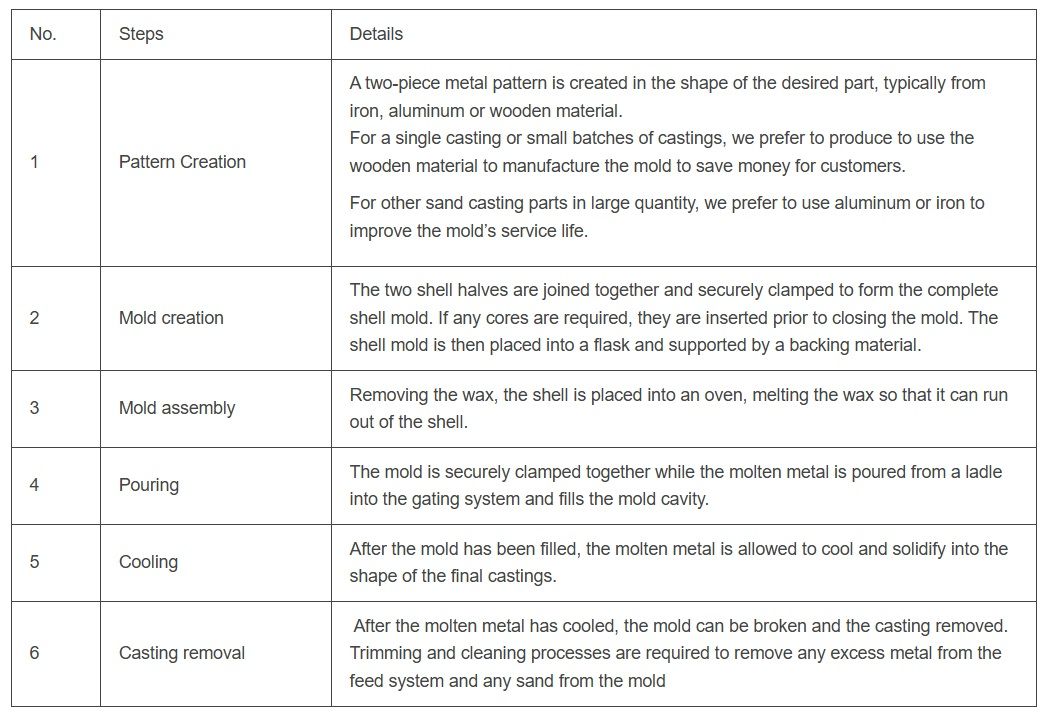

Metal casting process of cast iron products

Baoding Guokun casting factory can offer you green sand casting process, resin sand casting process or shell mold casting process.

The process of Baoding Guokun sand casting involves several steps after producing a professional tool or mold, including:

Ductile iron sand casting technique steps

A High Quality China Foundry!

Guokun Casting, of Baoding Hebei is an ISO 9001-2008 registered iron and steel foundry & supplier of high quality carbon steel, cast iron and machined castings used in power, mining, railway, agricultural, tillage, truck, automobile, pump, valve, motor, pipe fittings and gear industry.

With a monthly capacity of 10,000kgs and with more than 15 years of experience ensure the short delivery and the highest valued iron & steel casting parts.

Baoding Guokun can produce various ductile iron castings, ductile cast iron castings, grey and ductile iron casting, thin wall ductile iron casting, ductile iron casting parts, ductile iron casting companies, ductile iron and cast iron, ductile iron casting tolerances, ductile iron casing, ductile iron casting manufacturer, ductile iron casting supplier, ductile iron casting foundry, ductile cast iron, sg iron casting, ductile cast iron pipe casting, ductile cast iron pump housing, cast ductile iron, ASTM A536 ductile iron castings as per your drawings and samples.

Baoding Guokun Machinery Co., Ltd.

Baoding Guokun Export and Import Trading Co., Ltd

Office Add: 777# Chaoyang South Street, Baoding City, Hebei, 071000, China

Factory Address: Wangdu County, Baoding City, Hebei, 071000, China

Website: www.metalcastingfactory.com

Tel: 86-312-5951319 Fax: 86-312-5951296

Phone: 86-181 3278 9710 (WhatsApp & WeChat)

Email: gina@guokuncasting.com or gina.guokun@gmail.com