Pump Impeller

The pump impeller is the rotating component in the pump that directly transfers the energy from the motor into the fluid being pumped.

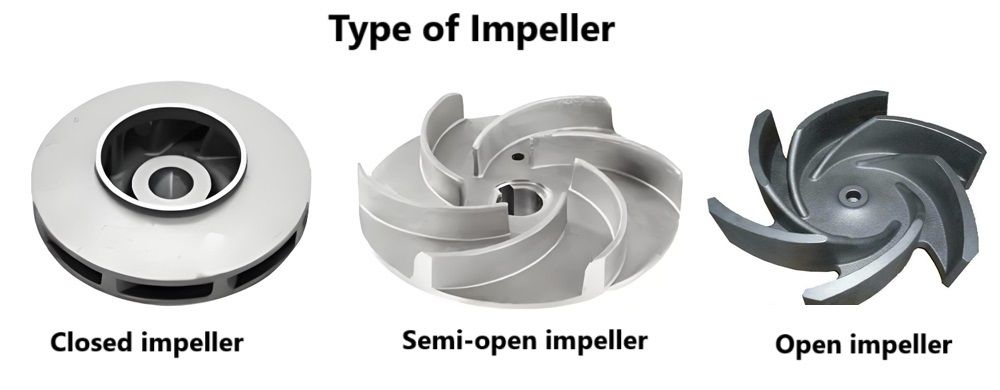

Pump impellers are classified as one of three types: Open impeller, semi-open impeller, or closed impeller. Their classification is based on whether they have a protective shroud or not.

| Impeller type | Details | Application |

| Closed impeller | The construction of enclosed impellers includes additional back and front walls on both sides of vanes that enhances its strength. The efficiency of closed impellers is higher. But the more complex design leads to higher production costs than open impellers. | They are generally used in large pumps, centrifugal pumps and clear water applications. |

| Semi-open impeller

|

The semi-open impeller is very similar in its design to the closed impeller. The one major difference is the absence of the front shroud. The additional back wall, giving it more strength. | The semi-open impellers or semi-closed impellers are usually used with liquids or mixed solid-liquid products. Mainly, they are well suited for medium sized pumps. |

| Open impeller | An open face impeller doesn’t have a back or front wall, only have blade and blade reinforcement. Without walls making open impellers slightly weaker than closed or semi-closed impellers. The number of open impeller blades is 2~6. | Open impellers are generally operating at higher tip speed and easier to clean and repair. Open impellers are usually used in smaller pumps and pumps that handle suspended solids and less to clog. |

Impellers are made from a variety of materials, including stainless steel, cast iron, bronze, aluminum, austenitic stainless steel, titanium, etc. When you choose the suitable material for pump impeller, you should think about the following several factors, strength, fluid compatibility, abrasion resistance, environmental conditions, type of liquid being pumped, casting and machining properties, etc.

Baoding Guokun can offer you the most suitable material as per your pump’s requirements. And with 25 years casting experience, we can produce the custom pump impellers with the suitable cast metal and casting process.

| Product name | Material | Casting process |

| Pump impeller | 300 series Stainless steel, 400 series stainless steel, low-carbon steel, alloy steel, mild steel, cast steel | Investment casting ( lost wax casting) |

| Cast iron, ductile iron, grey iron | Sand casting, lost foam casting | |

| Bronze, Nickel-aluminum bronze, brass, aluminum, etc. | Sand casting or gravity casting for aluminum pump impeller |

What’s the best material for a pump impeller?

Stainless steel is the most common pump impellers material because of its anti-corrosive, anti-heat and anti-contamination properties. The Baoding Guokun stainless steel casting pump impellers are made as investment casting process, or lost-wax casting process that results in a significantly improved surface finish & casting tolerance and impeller quality than other sand cast bronze pump impellers.

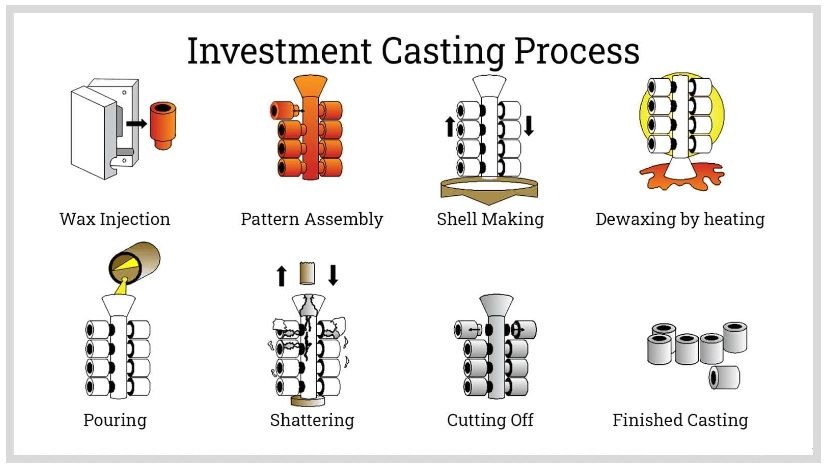

Baoding Guokun Investment casting stainless steel pump impeller’s steps:

- Patterns Makings: Creating a wax mold of the desired stainless steel pump impellers, and then adding sprues to the wax model to create a tree-like structure.

- Shell Building: Coating the wax pattern with a layer of fire-resistant paint, and then to be sprinkled with sand, so after a period of hardening, the surface will form a layer of fire-resistant thin shell.

- Dewaxing: Removing the wax, the shell is placed into an oven, melting the wax so that it can run out of the shell.

- Pouring: Pouring the molten stainless steel into the shell, and waiting for solidification under room temperature.

- Post treatment: After cooling, knock the shell and cut the sprue gate by grinding machinery to achieve net shape impeller castings. Then shot blasting to move mill scales to assure the smooth casting surface.

- CNC Machining & Balancing