Stainless steel is a type of low-carbon steel that is resistant to corrosion and rusting. It is made from iron, chromium, and other elements, such as nickel, carbon, molybdenum, and nitrogen. The chromium content in stainless steel is at least 10.5%, which creates a chromium oxide layer on the surface that protects the material from further oxidation.

Stainless steel has many properties, including corrosion resistance, durability, temperature resistance, recyclability, maintenance, modern appearance, high tensile strength, good ductility and high hardness. The stainless steel can be used in many different industries, such as automotive, aircraft, construction, marine, medical, food, etc.

The common stainless steel grades

| stainless steel alloys | |||||||

| Grades | Chemical Composition | Mechanical Properties | |||||

| C | Cr | Ni | Mo | Tensile Strength MPa |

Yield strength Mpa |

Elongation % |

|

| 304 | ≤0.08 | 18 ~ 20 | 8 ~ 11 | – | ≥520 | ≥205 | ≥45 |

| 304L | ≤0.03 | 18 ~ 20 | 8 ~ 12 | – | ≥480 | ≥175 | ≥45 |

| 316 | ≤0.08 | 16 ~ 18 | 10 ~ 14 | 2 ~ 3 | ≥520 | ≥205 | ≥45 |

| 316L | ≤0.03 | 16 ~ 18 | 10 ~ 14 | 2 ~ 3 | ≥480 | ≥175 | ≥45 |

| 410 | ≤0.12 | 11.5 ~ 13.5 | ≤0.75 | – | ≥440 | ≥205 | ≥20 |

| 430 | ≤0.12 | 16 ~ 18 | ≤0.75 | – | ≥450 | ≥205 | ≥22 |

The most common stainless steel alloy is austenitic stainless steel, particularly Grade 304 and Grade 316, which is a mixture primarily composed of Cr and Ni, offering good corrosion resistance and excellent formability, making them widely used in various applications.

The main difference between 304 and 316 stainless steel is the addition of molybdenum in 316, which gives it superior corrosion resistance. Please the above chart, you can judge that the stainless steel 316 and 316L are with 2~3% Mo, which improves the alloy’s resistance to acids, alkalis, and chloride pitting. The more corrosion resistance of 316 allows it to be used in highly acidic environments that other steels can’t tolerate without incurring damage. And ASTM 316 can be used in sea and marine applications because 316 can withstand exposure to salt and chlorides without breaking down.

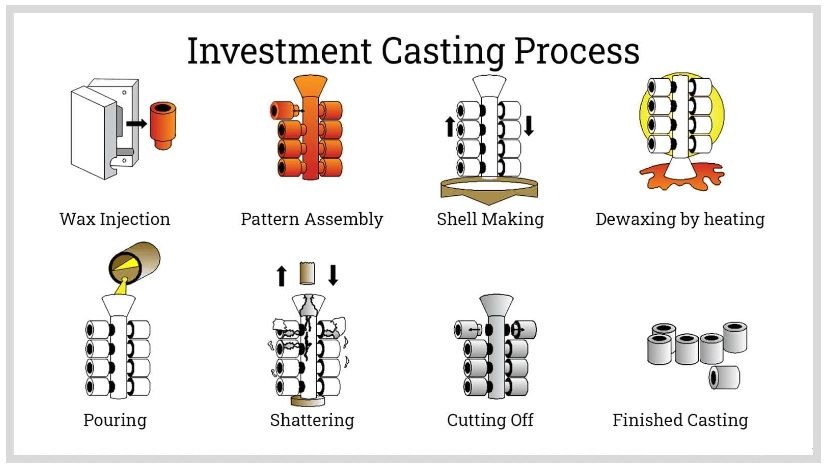

Baoding Guokun, with 25 years casting experience, can produce various stainless steel investment casting for various industries. Lost wax investment casting process can produce complex parts that are near-net shape. The stainless steel lost-wax casting parts manufactured by Baoding Guokun is with complex shapes, tight and accurate tolerances that have a standard of +/-0.005, fine surface finish 125 μin (3.2 μm Ra), minimal machining to reduce time and cost and cost-effective.

Baoding Guokun Machinery Co., Ltd.

Office Add: 777# Chaoyang South Street, Baoding City, Hebei, 071000, China

Factory Address: Wangdu County, Baoding City, Hebei, 071000, China

Website: www.metalcastingfactory.com

Tel: 86-312-5951319 Fax: 86-312-5951296

Phone: 86-181 3278 9710 (WhatsApp & WeChat)

Email: gina@guokuncasting.com or gina.guokun@gmail.com