Surface treatment of slurry pump end cover

The main steps of surface treatment for slurry pump end caps include surface treatment, coating application, and curing process.

surface treatment

- Sandblasting treatment: Sandblasting process is carried out on the surface of the casting pump back liner to remove the oxide layer and impurities, ensuring that the investment casting surface is rough, clean, and dry. After sandblasting treatment, it is not allowed to directly contact the lost wax casting surface of the pump back plate with grease gloves to prevent contamination.

- Cleaning: Use alcohol, acetone, ethyl acetate, or specialized cleaner to clean the surface of the slurry pump casting parts, ensuring that there is no grease or impurities.

Coating construction

- Bottom glue coating: Apply bottom glue evenly on the area to be repaired, ensuring that the glue layer is fully immersed in the substrate.

- Glue mixing: Mix the wear-resistant coating evenly in proportion, and pay attention to preheating before mixing to increase viscosity.

- Glue application: Before the base adhesive solidifies, spread the evenly mixed wear-resistant coating layer by layer on the area to be repaired, and compact it with a rubber hammer or other tool to avoid voids in the adhesive layer.

Curing process

- Preliminary curing: Leave it at room temperature for 8 hours for preliminary curing to form.

- Heating and curing: Heat the workpiece to 80-120 ℃ and hold for 2-3 hours to improve the comprehensive performance of the coating.

- Inspection and repair: After curing, carefully inspect the workpiece. Defective areas need to be re glued and repaired, and areas that exceed the tolerance need to be polished to the appropriate size.

Common problems and solutions

- Flowing phenomenon: After applying glue, it needs to be preliminarily cured and then heated to complete the curing process to avoid flowing phenomenon.

- Sealing issue: There is no sealing ring between the front and rear plates of the pump and the volute, and it is completely sealed by a tapered shape. The precision requirement is high, and the sealing effect needs to be ensured.

Through the above steps, the wear problem of the slurry pump end cover can be effectively addressed, extending its service life.

Baoding Guokun is a 25 years’ experience casting factory in sand molding process and investment casting process for pump parts, pump housing, pump casing, pump back liner, pump volute, pump diffuser impeller, pump impeller, pump expeller, pump lower strainer, pump rear cover, pump volute casing and other custom pump casting in cast iron, cast steel and aluminum alloys.

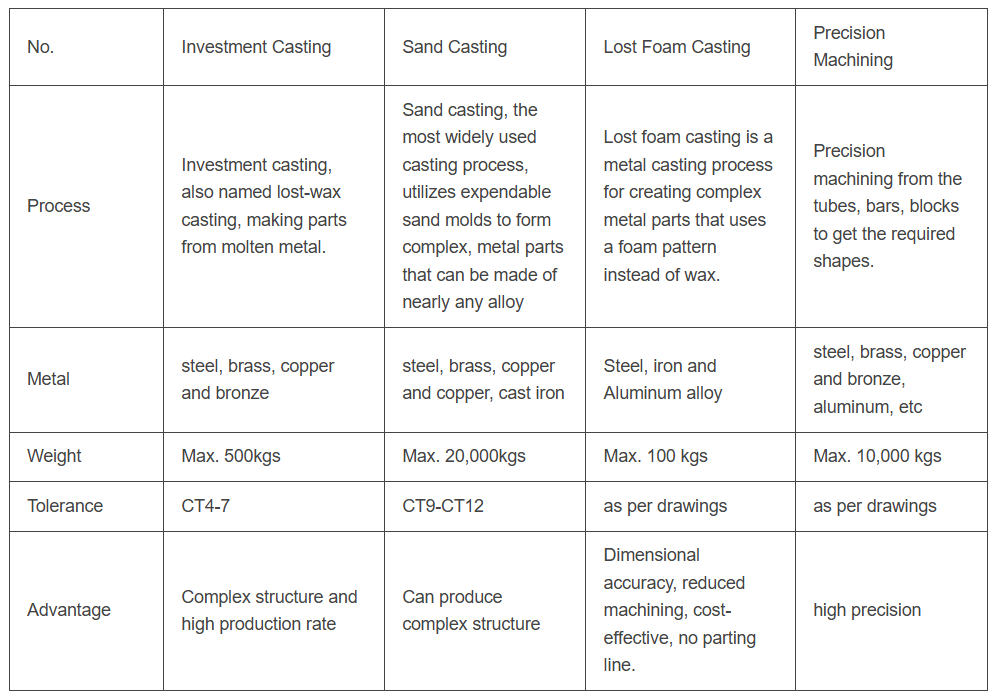

Baoding Guokun metal casting process

Baoding Guokun Machinery Co., Ltd.

Office Add: 777# Chaoyang South Street, Baoding City, Hebei, 071000, China

Factory Address: Wangdu County, Baoding City, Hebei, 071000, China

Website: www.metalcastingfactory.com

Tel: 86-312-5951319 Fax: 86-312-5951296

Phone: 86-181 3278 9710 (WhatsApp & WeChat)

Email: gina@guokuncasting.com or gina.guokun@gmail.com